MOP

MOP® is a software tool for optimizing, expanding, reconstructing and verifying the operation of existing heat networks and for planning and designing of new heat networks, based on complex thermo-hydraulic calculations, both steady-state and dynamic.

It serves to DHS designers and DHS operators for:

- solving various engineering, designing and optimization tasks, including dimensioning of pipes, pumps, valves, mixing and shunts;

- flow analysis or hydraulic operational state analysis,

- optimizing output parameters from sources (temperature, pressure), pump operation, maintaining a stagnation pressure level and refilling the medium,

- balance and optimization tasks related to heat loss calculation, pumping work, etc., and

- other tasks related to the operation of heat networks.

MOP has gradual learning curve. The product can satisfy customers with simple problems as well as the most demanding customers with the need to integrate with GIS, control systems, online measurement and other business systems. Tutorials for some example tasks are published on a YouTube channel.

Features of the product includes modelling of:

- water and steam heat networks (steam pipes including condensate running down at the bottom),

- complex topological structures containing many loops and many heat sources,

- large networks with volume loss calculations,

- pumps, pressure control valves, stop valves, mixing and shunts;

- overall energy balance including heat losses,

- superheated and wet steam flow including steam traps calculation,

- island mode operation,

- network dynamics including heat accumulation in pipings,

- dynamic consumption model using artificial neural networks.

The calculation of the model is stable, fast and accurate. The product is highly configurable and extensible and has extensive interoperability with other systems such as SCADA, control and online measurement systems, GIS systems, SQL databases, office suites.

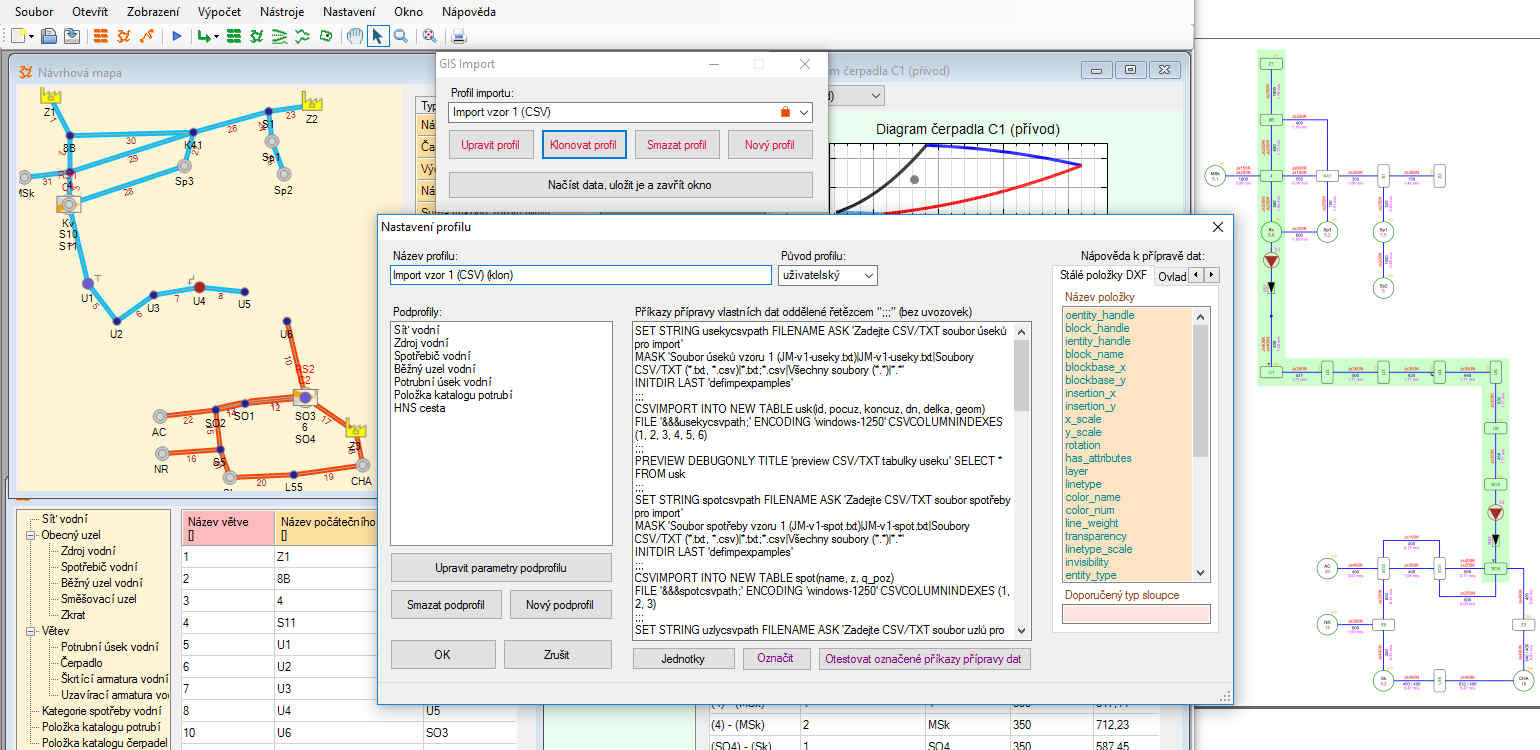

MOP allows both graphical editing and viewing of data in its own graphical interface, as well as the possibility of preparing and processing data in a spreadsheet.

Data import is possible from various GIS systems. Export can be done for wide range of SQL database systems.

The tool can also significantly help with rapid generation of rectangular calculation schemes.

With the Online module it is possible to take measured values from the control systems and also to import plans for the future, while the results of the model can be exported to the control system as planned values.

Customer can ask for specific retail configurations from individual MOP modules. Each license comes with a standard technical support including hot-line, consulting and free update to new versions when they are available.

MOP is fully localized in English and Czech language and it is ready for customizing into other languages and cultures.

ORTEP, s.r.o. also offers own creation and maitenance of heat networks calculation models using MOP software.

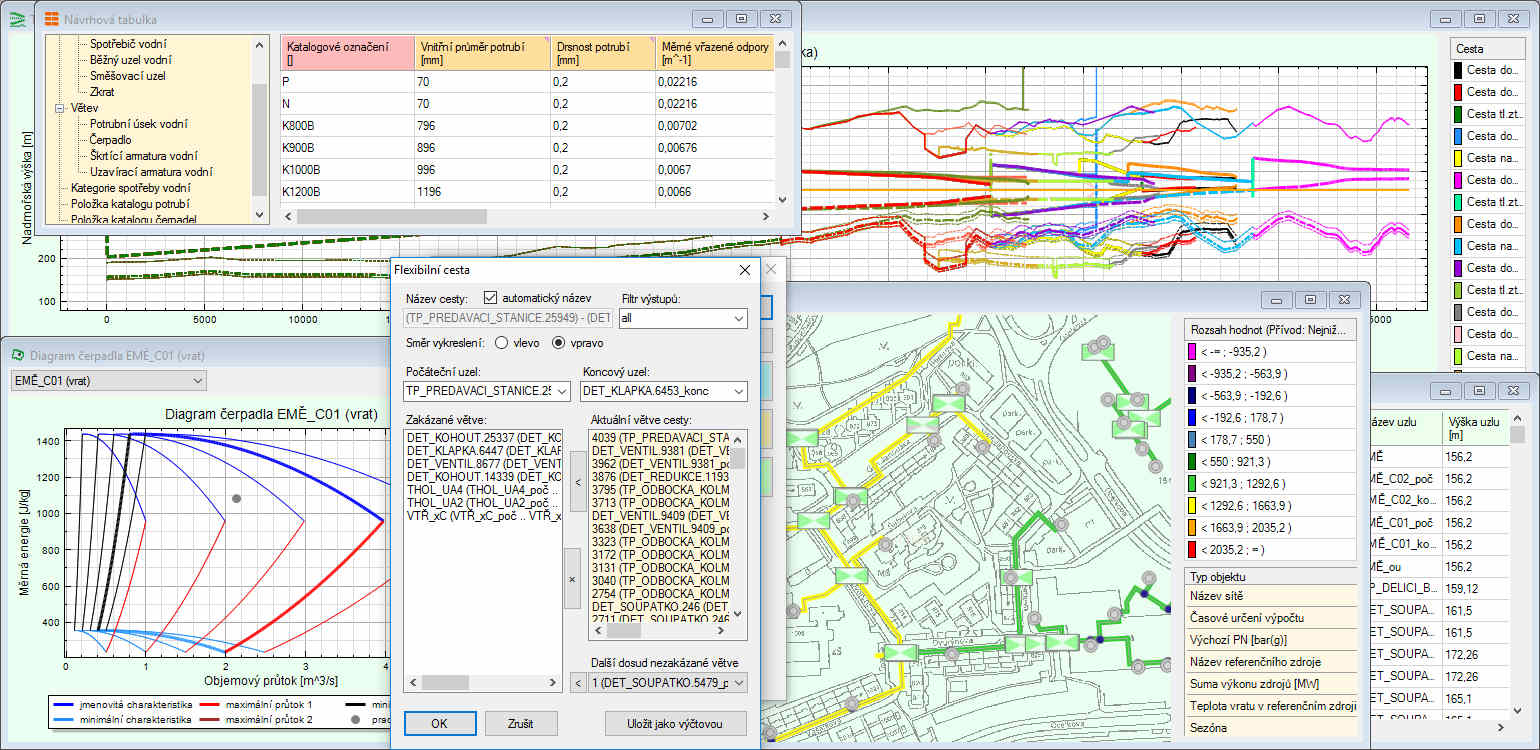

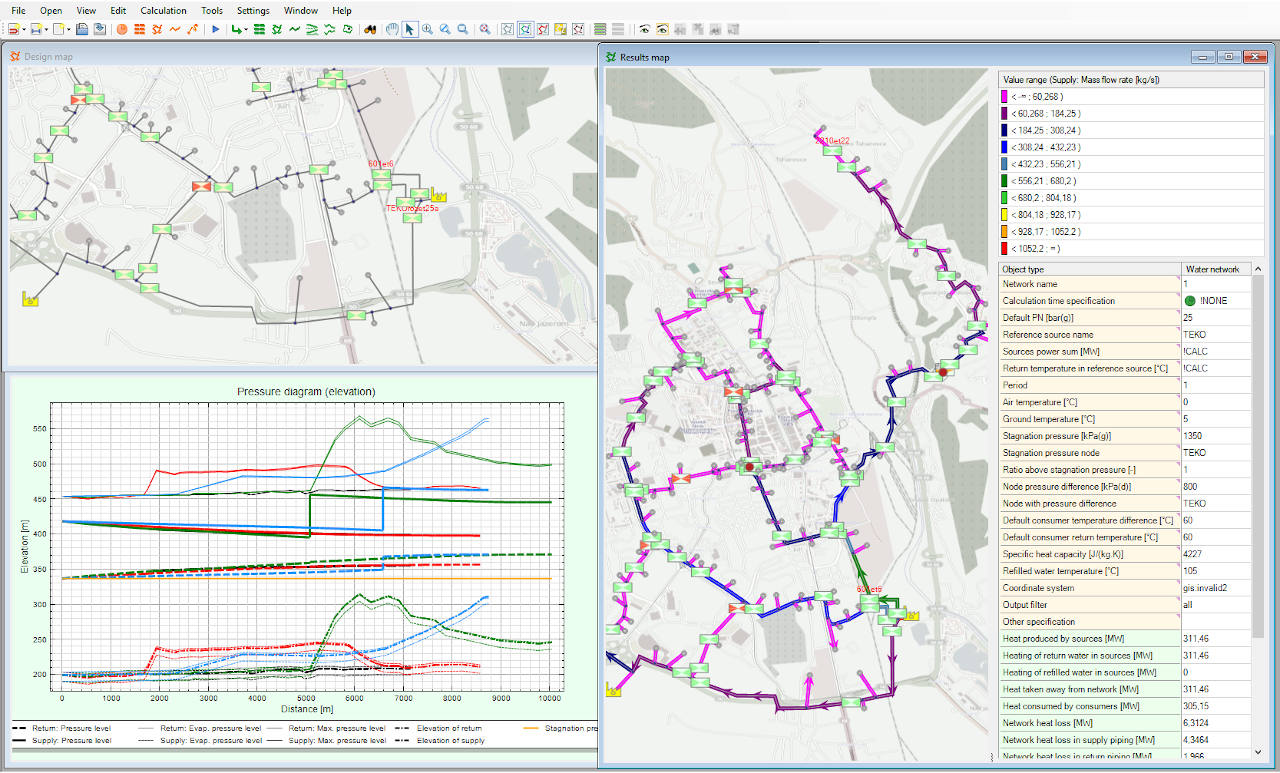

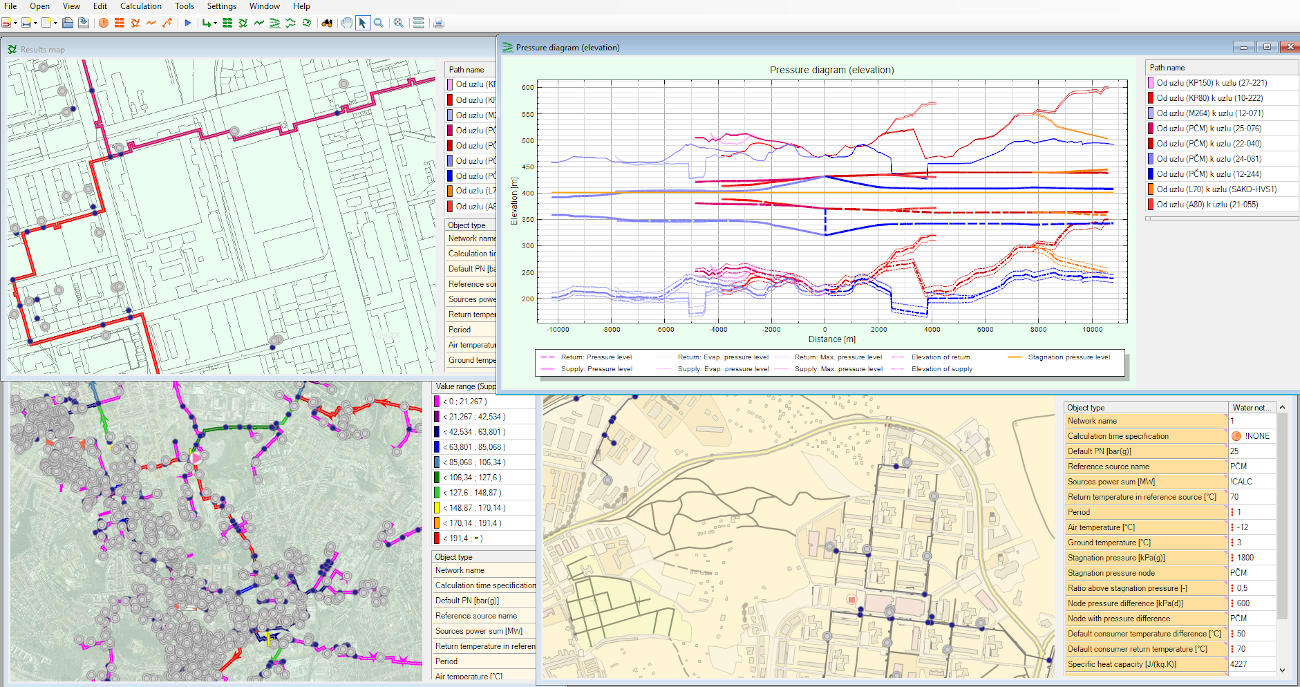

Graphical user interface – a model editor and result viewer

The system is carefully designed to offer many options, yet to be clear, intuitive and easy to use.

The model is usually based on GIS spatial data, but model calculations can be performed without any spatial information.

With MOP user interface, the user can:

- edit any part of input model data (in tables or in a spatial map view),

- create new pipes, nodes, pumps, sources, etc.;

- display and print pressure diagram and pump operation diagrams,

- display MOP result data in a spatial map view (e.g. color scales of velocity, temperatures, pressures or any other result quantity can be presented), in tables or in time series charts;

- create and use own new input and output parameters and connecting them with other parameters by custom formulas,

- view offline and online background maps in the network spatial map view windows,

- visually compare data from different models and share desktop layout across multiple models.

Spreadsheet front-end

The spreadsheet front-end allows user to save, edit and view the model as a MS Excel file and control other MOP modules from the spreadsheet, such as running calculations, loading results or running the graphical interface and other functions.

Every model can be extended with custom cascading calculations, dependent tables, charts and reports according to customer needs, e.g. displaying of pump operation point with characteristics within a pressure diagram. Also, the model inputs can be connected to custom calculations, so a model can be extended e.g. by master formulas of pressure control etc.

GISimport – an import module

GISimport is a widely configurable module for importing input data into the MOP system. Data can be obtained from GIS or from a SQL database. (Supported database systems include Microsoft SQL Server, Oracle, PostgreSQL, MySQL, MariaDb, etc.) Spatial information can be loaded from OpenGIS WKT (most database systems supports this), from vertex coordinates table (any database system), ESRI Shapefile, AutoCAD DXF or from a text file. This module is useful in all cases where spatial information and other pipe parameters are managed centrally.

SQLexport – an export module

SQLexport is a configurable module that allows exporting input and output data to a SQL database. (Supported database systems include Microsoft SQL Server, Oracle, PostgreSQL, MySQL, MariaDb, etc.) This module can be used to reverse transfer pipe parameters back to GIS or generally to a database store for further processing.

Scalagen – creating a rectangular schema

With Scalagen module, the user can create standard rectangular schema of modelled network. Schema can be extended by any information available from input and output MOP data, e.g. velocity or flow in pipes or pressure in nodes etc. When a schema in Scalagen is already designed and these values changed, the updated schema is a matter of no more than two clicks.

Online – connection to a real-time measurement system

The Online module allows user to display measured values from a real-time measuring system along with the model inputs and outputs. It also allows (beside simulation mode) use prediction and analytical mode – like in DYMOS.

phone: 283 840 357, 283 840 355; web: www.ortep.cz; e-mail: ortep@ortep.cz