DYMOS

DYMOS® is a software system designed for dispatcher control and operation optimization of district heating systems. The system can be used for heat consumption and electricity production predictions, for daily operation planning, for optimizing supply-water temperature including heat accumulation, need of additional heat sources operation, daily analysis of hydraulic conditions, operation of circulation pumps, etc..

Complete delivery of the DYMOS system includes not only the creation of the main calculation model, but also its connection to measurement systems, as well as training, maintenance and technical support.

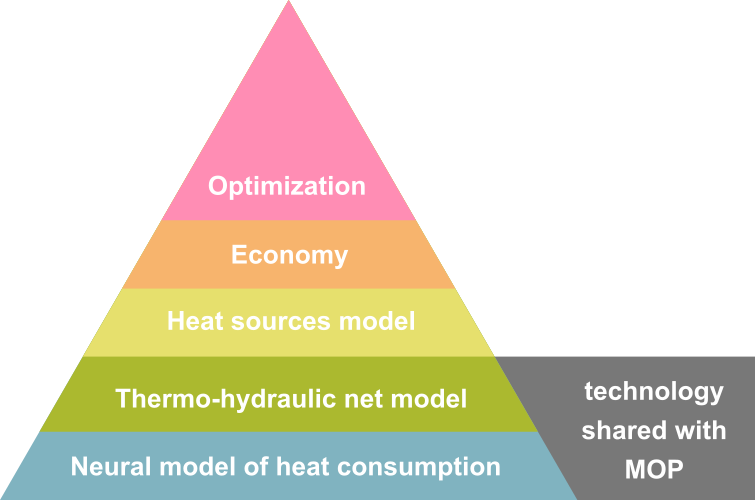

The software is based on a complex dynamic simulation model of heat production, distribution and consumption.

The software uses the same technology for the thermo-hydraulic network calculations and the neural model of heat consumption as MOP, but unlike MOP, it is adapted for specific optimization tasks requested by a particular customer.

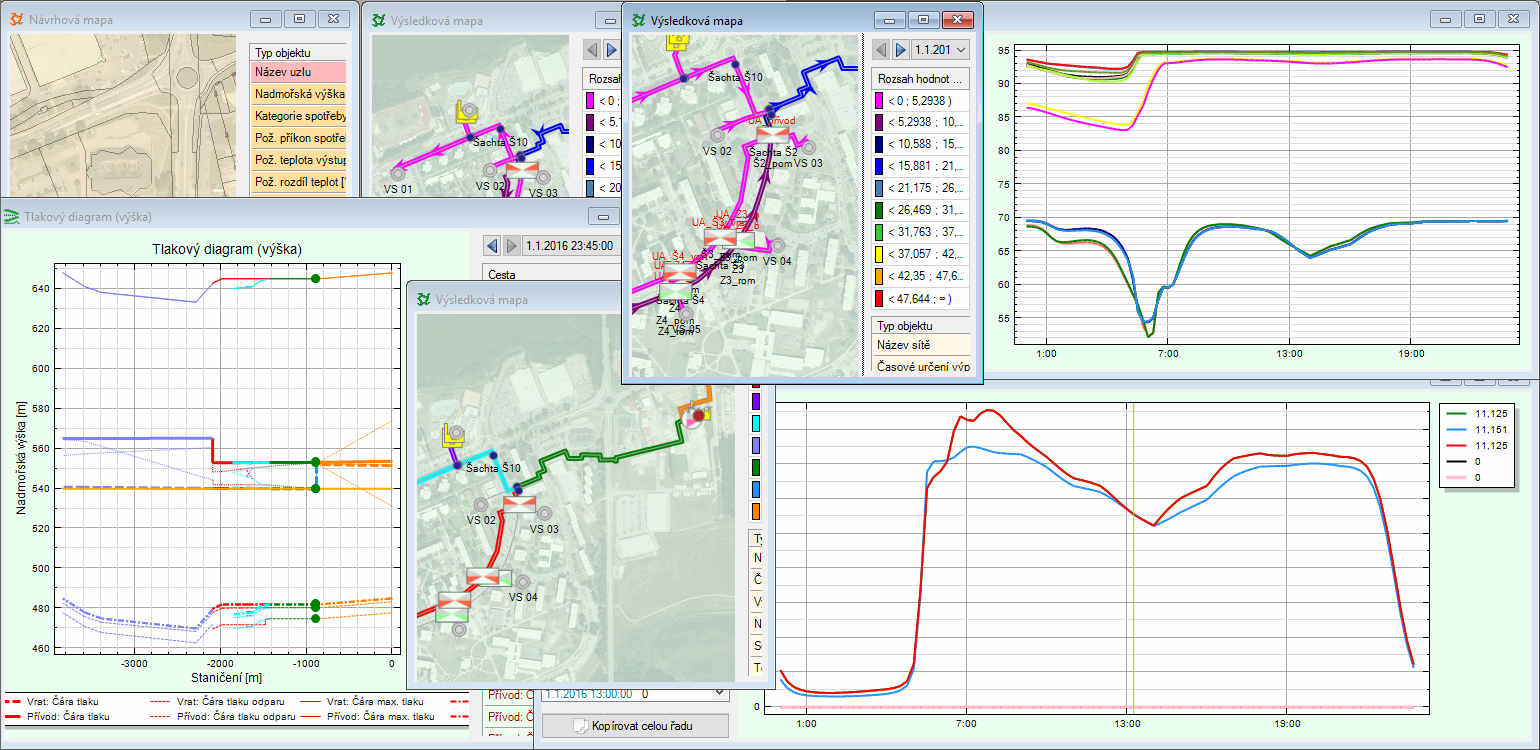

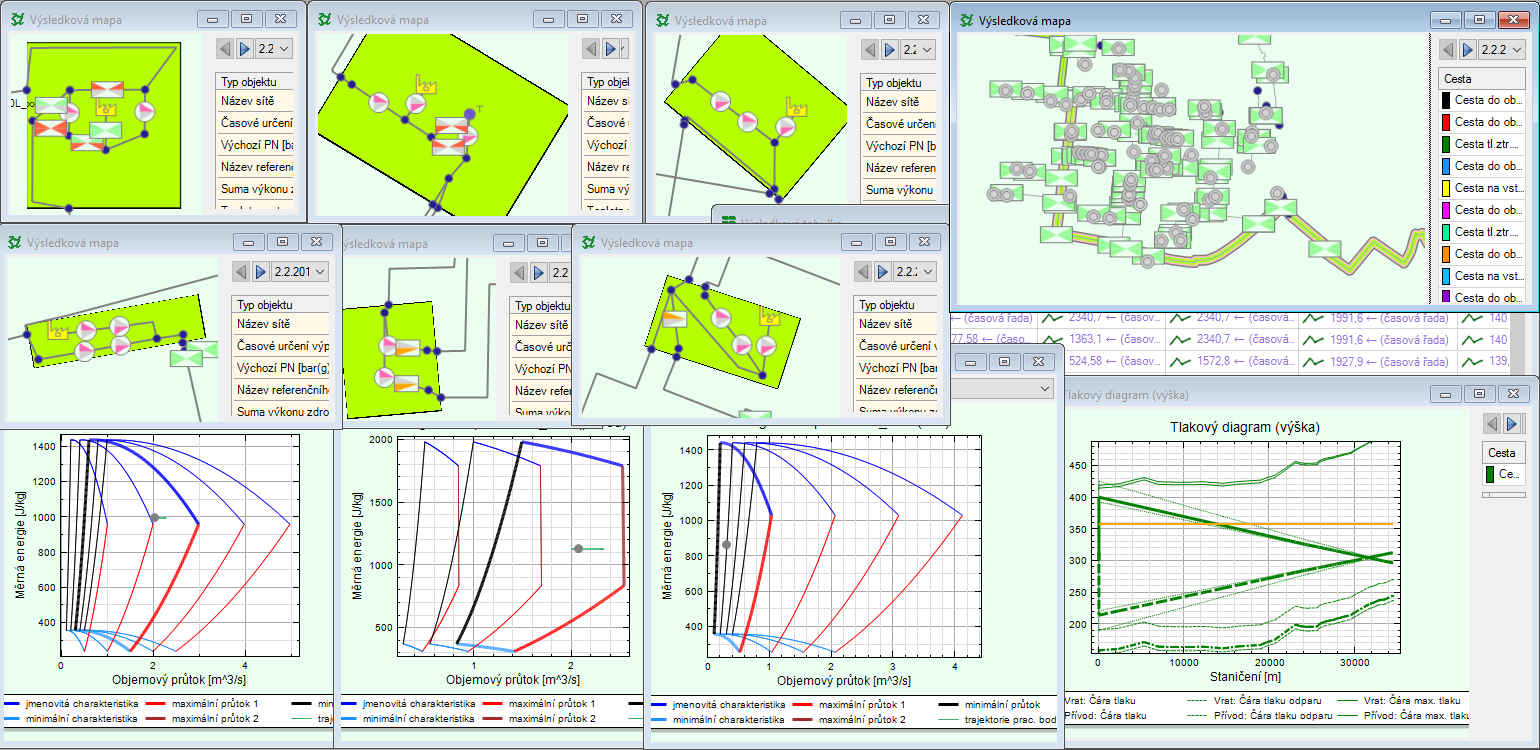

DYMOS shares with MOP also the main user interface (that can use spatial map display of the network, display pressure diagrams, pump operation diagrams, off-line and on-line background maps, etc.) and extension modules.

The product is highly configurable and extensible and has extensive interoperability with other systems such as SCADA, control and online measurement systems, GIS systems, SQL databases, office suites.

DYMOS allows graphical editing and viewing of model data in its user interface. The model of the network can be freely edited (creating and deleting network elements and changing their parameters) except for some locked parts of the network (related to tailor-made algorithms).

Data import is possible from various GIS systems. Export can be done for wide range of SQL database systems.

With the Online module it is possible to take measured values from the control systems and also to import plans for the future, while the results of the model can be exported to the control system as planned values.

The system is carefully designed to offer many options, yet to be clear, intuitive and easy to use.

In addition to the MOP features, DYMOS also offers e.g. the following technologies:

- Control of hot-water output temperature allows to utilize controlled heat accumulation.

- Various detailed models of boilers, turbines, and other source devices make it possible to calculate the available and forced electrical power.

- The layer of economics allows, based on the prices of commodities sold and purchased, to count sales and costs within the period under review and, on this basis, it is possible to compare the economic viability of the individual operating options.

- The DYMOS system also includes selected optimization algorithms, such as optimal redistribution of the power of the individual sources in the system while meeting defined boundary conditions.

DYMOS is fully localized in English and Czech language and it is ready for customizing into other languages and cultures.

The Online module allows user of DYMOS system to display measured values along with the model inputs and outputs and also to operate in a prediction and analytical modes. The prediction mode serves for the system behaviour prediction in near future, while the analytical mode serves for the analysis of past operational situations. The simulation mode allows modeling of any historical or future operational options.

Planning for future operation states

Prediction mode is primarily used in operation planning to predict heat supply and electricity production for one or several days ahead. It can be used in the process of short-term electricity trading, eventually for subsequent checks and observance of contracted supplies.

Simultaneous display of measured and model values, where the charts display the overlap of predicted and measured values, allows user to track the quality of the prediction, or to respond to new situations.

The so-called continuous predictor allows updating the prediction that combines the current settings for future operation with updated real measurements.

Analysis of past operating states

Analytical mode serves for a detailed examination of historical operating conditions and changes.

Simulation of operational changes

Simulation mode makes it possible to create and study different operating variants for any outdoor temperature without any connection to the actual state of the system. This mode is designed to build long-term production plans (month, year, ...) and to elaborate conceptual materials for long-term system development and optimization.

phone: 283 840 357, 283 840 355; web: www.ortep.cz; e-mail: ortep@ortep.cz